Superior Quality

Customer Service

Product Education

Gabriel First Corp.

Your Trusted Partner for

At Gabriel First Corp., we empower professionals in the janitorial and sanitary industries to raise the standards of cleanliness. We offer specially formulated and eco-responsible cleaning products, one-on-one consulting and training services, and complete access to our digital library of training videos and educational printouts.

We proudly partner with businesses who are as serious about clean as they are about their bottom line. Many companies have found that our products and methods enable their crews to get a better clean in less time, while they spend less on product replenishment. In addition, we believe in offering our customers a full-service experience that doesn't end after a purchase. Our cleaning specialists will work directly with janitorial leaders to ensure our products operate at peak performance in every situation.

Education is Key

By combining high-performance, eco-responsible products and unique housekeeping training programs, Gabriel First Corp. enables its customers to elevate their professional skills, optimize efficiency, and provide clean, safe, and sanitary environments.

While we take great pride in developing our specialized formulas, we believe knowing how to use them is key to getting the cleanest clean. By offering in-house consulting and online training programs, we aim to help streamline the janitorial operations that every workplace depends on. We understand that increasing efficiency and reducing costs are fundamental to any business.

Cleaning Guidance and Expertise

Eco Responsible Cleaning Products

Top Quality Housekeeping Training

Shop by Category

Experts in the Janitorial & Sanitary Industry Since 1964

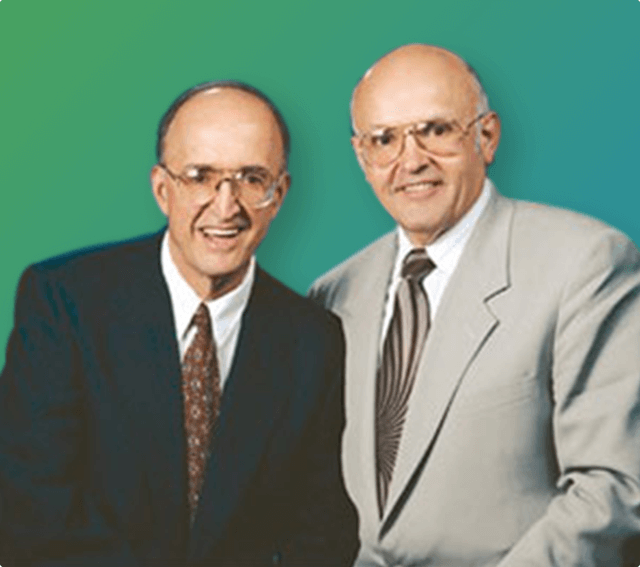

Founded by Joe and Gabriel Zanche, the Gabriel First Corp. serves facility owners and workers across America with high-performance cleaning products and unique housekeeping training programs.

The Gabriel First Corp. has spent almost 60 years carefully developing eco-responsible products and eliminating harsh ingredients. Our residue-free sanitary products remove germs instantly and reduce overall cost. On average, our customers save about 50% on labor and materials expenses after consulting and implementing our sustainable processes.

We believe that by combining personalized training and various educational materials with our high-quality product line, we’re investing in your success. When cleaning professionals are equipped with the right tools for the job, and the know-how to use them, they succeed far beyond expectations. With ever-changing cleaning and sanitation protocols, it’s essential to know your products and the most effective ways to use them.

Hospitals & Healthcare Facilities

Educational Facilities

Food Service Facilities

Products

Quality, Highly Concentrated Products

Every Gabriel First Corp. product has been carefully formulated to provide an exemplary clean. We’ve selected each ingredient to make a cleaning product that is highly effective and easy to use. Plus, many of our products are eco-responsible. Your teams can be proud to use these cleaning solutions, knowing they are doing something to look after their local environment.